Fully Automatic 7090 Cooling Pad Production Line for Poultry House High Efficiency

- DUO HUI

- Weifang City, Shandong Province, China.

- 25

- Produce by oneself

1.Full Automation Saves Labor Cost

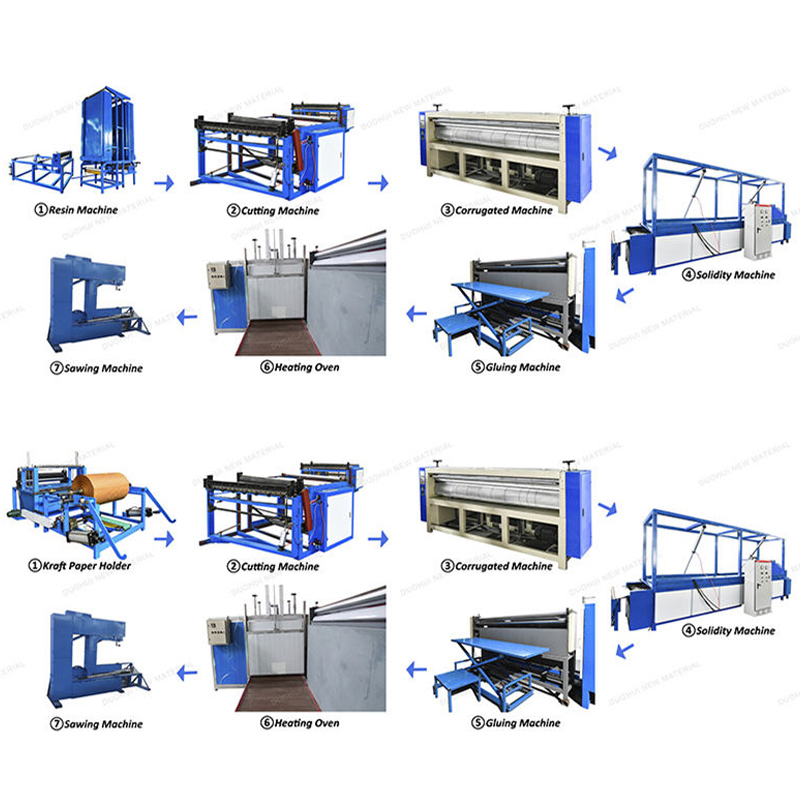

Integrated corrugating, impregnation, pressing and cutting processes, one-person operation only. Compared with semi-automatic machines, it reduces labor costs by 60% and is the best choice for large-scale poultry house cooling pad production.

2.High-Quality Cellulose Material

Adopts imported kraft paper and eco-friendly resin, the finished cooling pads have strong water absorption and long service life (3-5 years), adapting to the high-temperature and high-humidity environment in Southeast Asia.

3.Customizable Model

Supports 7090/5090 two mainstream models, and the width of the cooling pad can be customized from 0.5m to 2m, meeting the needs of different sizes of chicken farms and greenhouses.

Introduction

Looking for a high-output cooling pad production line for your poultry farm in Southeast Asia? Our fully automatic 7090 evaporative cooling pad making machine is specially designed for chicken, duck and pig farms in Indonesia, Philippines and Thailand. With a production capacity of 500㎡/h, this cellulose cooling pad production line can produce high-density corrugated cooling pads that lower the house temperature by 8-12℃, effectively improving livestock survival rate and growth efficiency.Full Automation Saves Labor Cost

Integrated corrugating, impregnation, pressing and cutting processes, one-person operation only. Compared with semi-automatic machines, it reduces labor costs by 60% and is the best choice for large-scale poultry house cooling pad production.

High-Quality Cellulose Material

Adopts imported kraft paper and eco-friendly resin, the finished cooling pads have strong water absorption and long service life (3-5 years), adapting to the high-temperature and high-humidity environment in Southeast Asia.

Customizable Model

Supports 7090/5090 two mainstream models, and the width of the cooling pad can be customized from 0.5m to 2m, meeting the needs of different sizes of chicken farms and greenhouses.

Model: 7090/5090 customizable

Production capacity: 300-500 ㎡/h

Automation degree: Fully automatic (PLC control)

Certification: ISO 9001, CE